Pallet Racking Inspection Training

Our specialized, on-site training course empowers your designated team members to confidently and competently carry out these essential regular checks.

This proactive approach to safety allows you to spot and address damage early, drastically reducing the risk of catastrophic failure and minimizing expensive repair costs.

This proactive approach to safety allows you to spot and address damage early, drastically reducing the risk of catastrophic failure and minimizing expensive repair costs.

The Necessity of Internal Inspections

While an annual Expert Inspection by a SEMA Approved Racking Inspector (SARI) is mandatory, it is legally insufficient on its own.HSE Guidance (HSG76) requires that every warehouse appoints P.R.R.S. (Person Responsible for Storage Equipment Safety);who must ensure weekly or regular internal inspections are performed.

Tailored Training Programs

We provide customized training packages designed to meet the specific needs of your team and the requirements of your workplace, enhancing knowledge and competency in racking management.

Practical,

On-Site Training

On-Site Training

The course includes an interactive classroom session followed by a hands-on inspection of your own warehouse equipment.

Course Highlights

Our one-day, practical course is delivered by a certified SEMA-Trained Racking Inspector and tailored to your specific racking system, ensuring maximum relevance and real-world application.

The Role of the P.R.R.S

Full understanding of legal responsibilities under PUWER (Provision and Use of Work Equipment Regulations) and HSE guidelines.

Racking Component Recognition:

Identify the critical load-bearing parts

(uprights, beams, bracing, locking pins, etc.) and their structural importance.

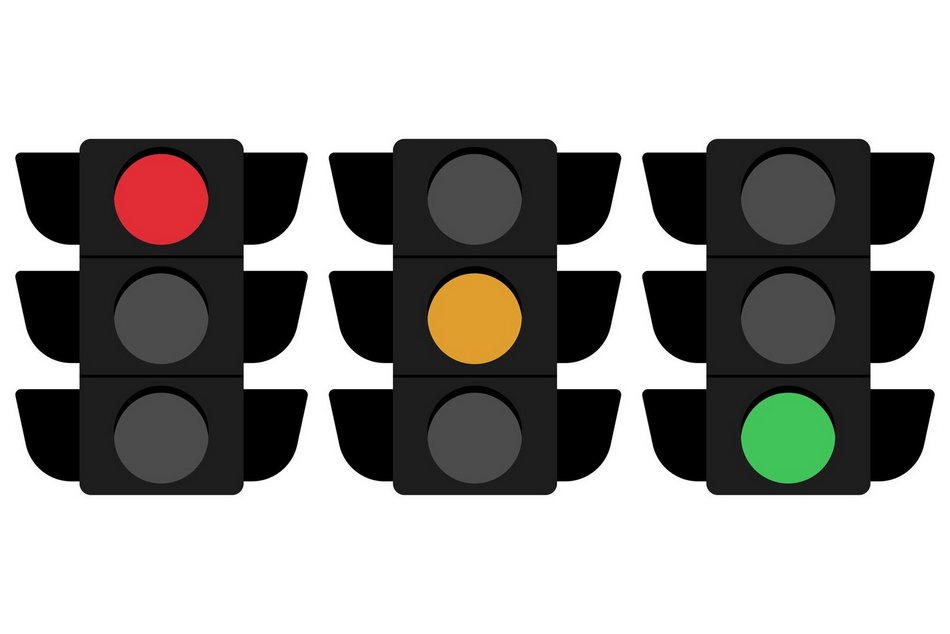

The SEMA Traffic Light System

Learn to accurately assess and classify damage severity into Red, Amber, and Green risk categories.

Reporting and Action:

Establish clear, auditable procedures for recording findings, offloading damaged racks, and implementing follow-up actions.

Damage Prevention:

Identify the common causes of racking damage and implement controls to prevent recurrence.

Inspection Reports

Receive detailed inspection reports that are tailored to your specific setup, enabling you to understand the condition of your racking systems

Contact Us for More Information

Benefits of Training Your P.R.R.S. In-House

Legal Compliance

Meet the HSE requirement to have a competent person conducting regular documented inspections.

Cost Reduction

Identify minor damage before it escalates into a major (and costly) repair or a full rack offload

Safety Culture

Empower your staff (managers, supervisors, fork truck drivers) to be part of the safety process, leading to a visible reduction in rack strikes.

Operational Continuity

Prevent unexpected rack failures that halt operations and jeopardize product flow and deadlines.

Auditable Records

Receive a Certificate of Competency (typically valid for 3 years) for each successful candidate, providing essential documentation for safety audits.

Who Should Attend?

This training is essential for anyone who will be designated as the Person Responsible for Storage Equipment Safety (P.R.R.S.) and for those who support the safety program. Warehouse Managers & Supervisors Health & Safety Officers Team Leaders Senior Forklift Operators

Ready to Secure Your Internal Racking Safety Program?

Get a custom quote for on-site P.R.R.S. training at your facility.

We train your team using your racks, for minimum disruption and maximum relevance.